The Hi FIXOLITE range

The Hi Fixolite range meets the most stringent standards for external thermal insulation (ITE), with a thermal resistance of up to 11. The block complies with the RE2020 and passive houses and BEPOS.

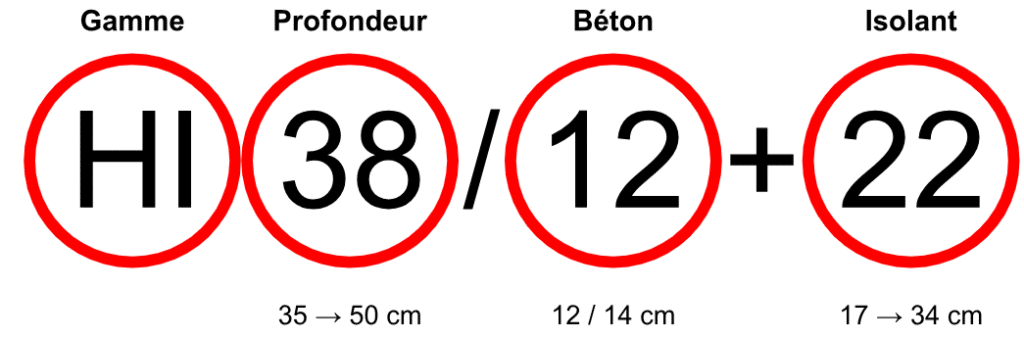

Hi blocks are referenced by their thickness according to the following nomenclature:

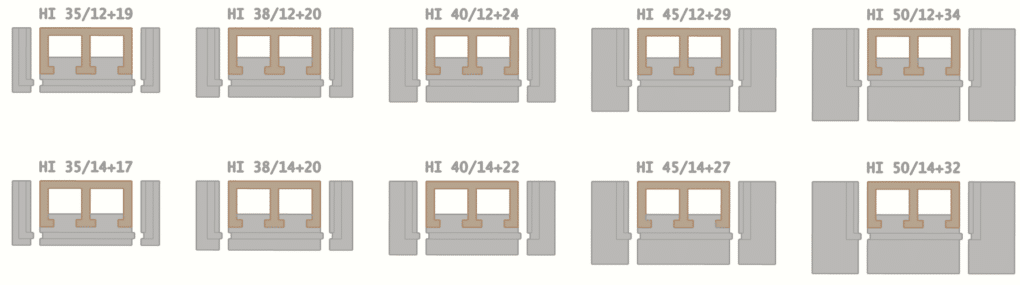

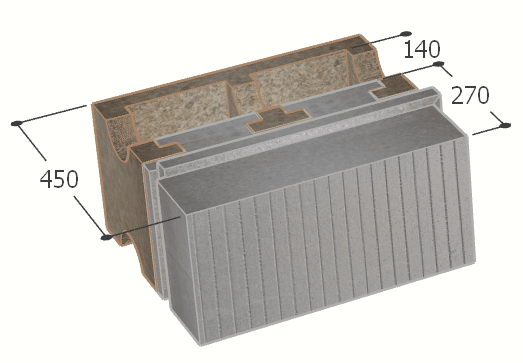

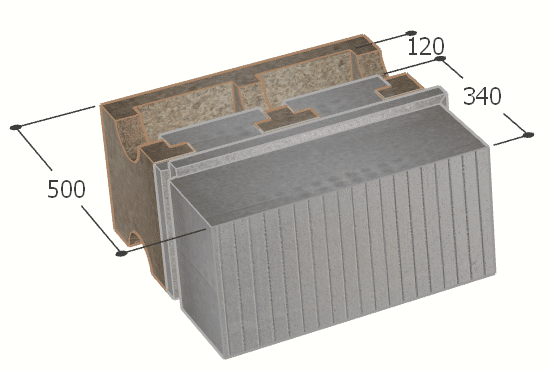

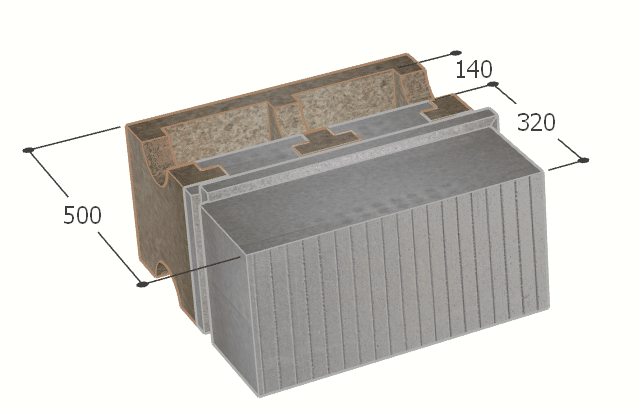

The Hi range comprises 10 different blocks (all based on the B-CL25/17 block) with polystyrene insulation thicknesses ranging from 17 cm to 34 cm:

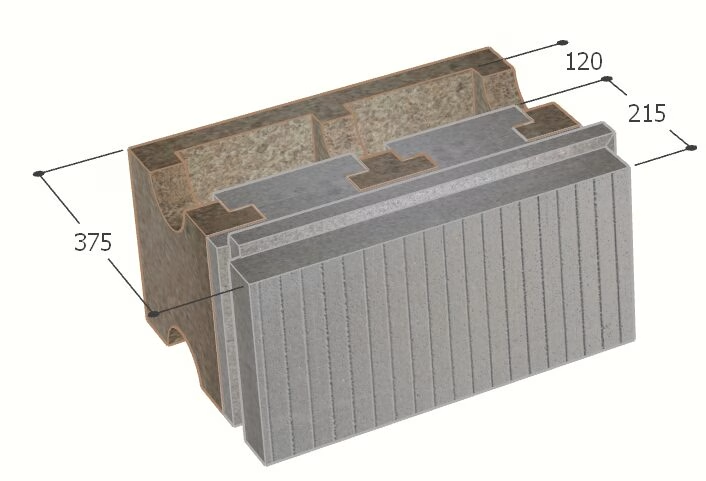

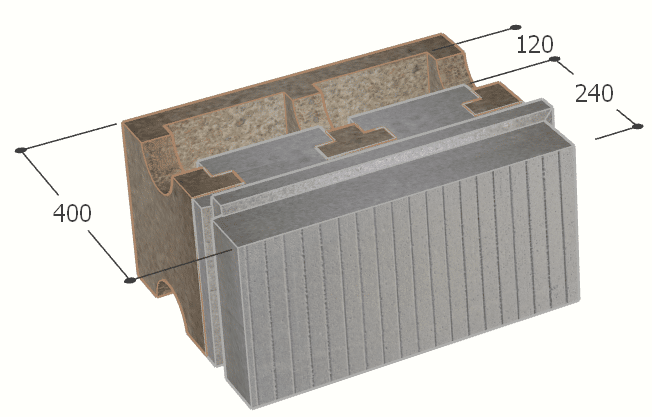

- 5 blocks with a 12 cm thick concrete shell

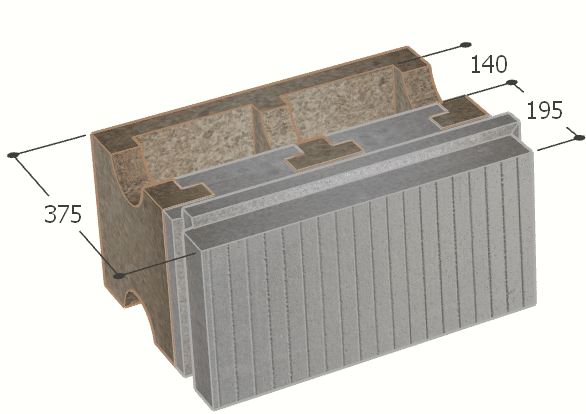

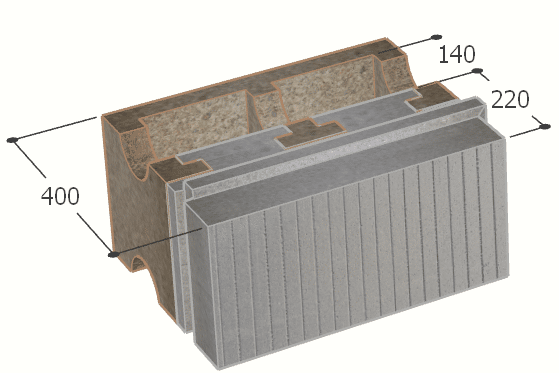

- 5 blocks with a 14 cm veil

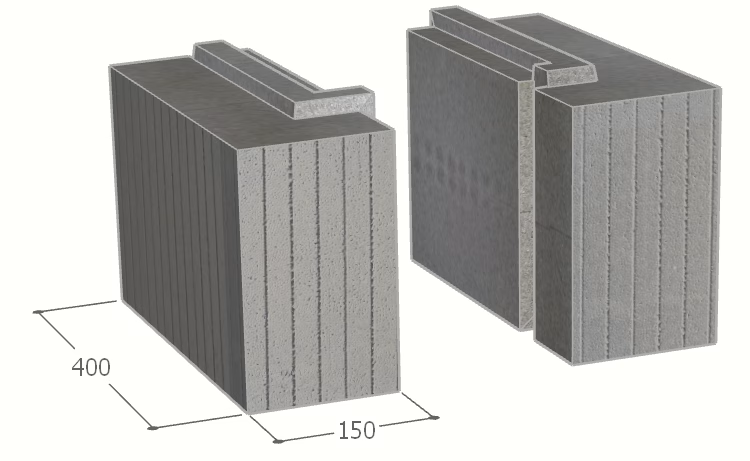

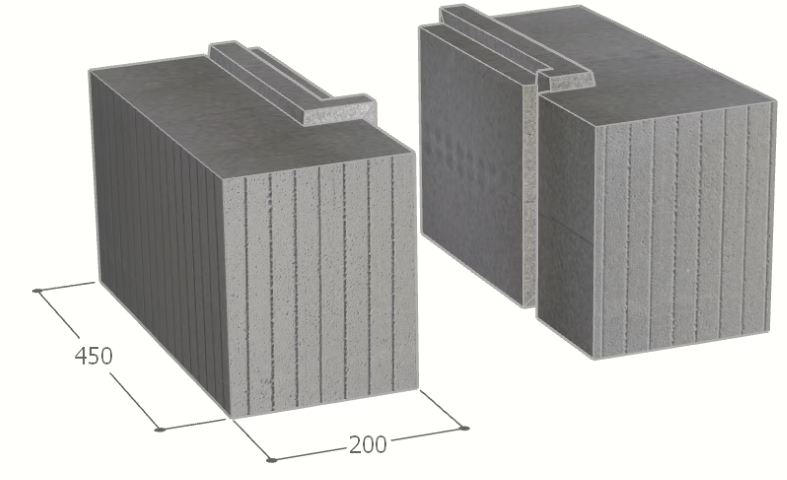

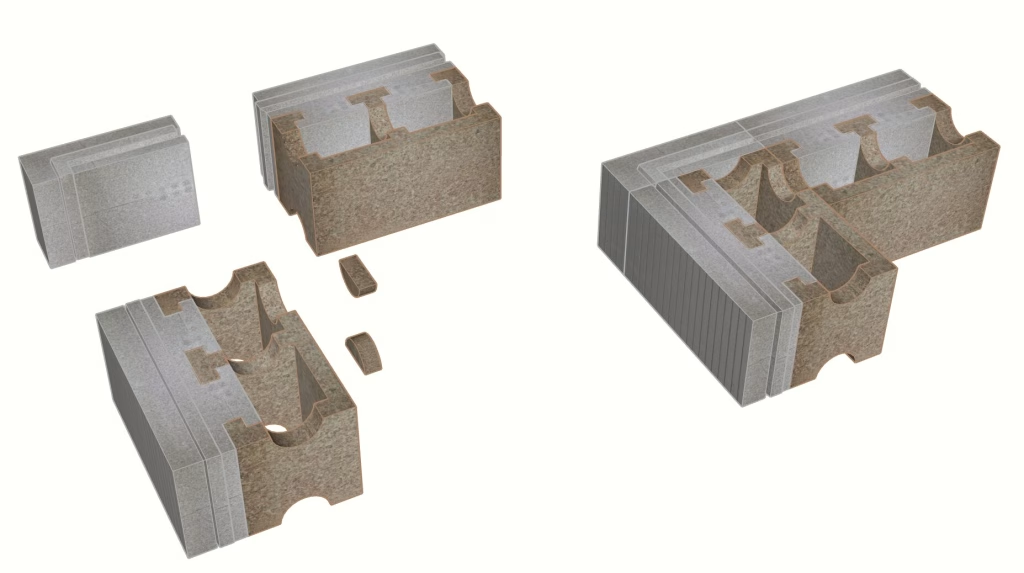

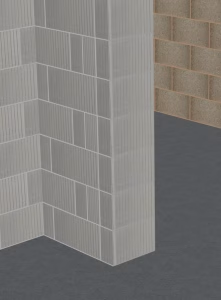

For each of the 5 widths, there are corner pieces (left or right angle - seen from the outside as in the diagram below). These parts are grooved polystyrene blocks with mortise and tenon joints:

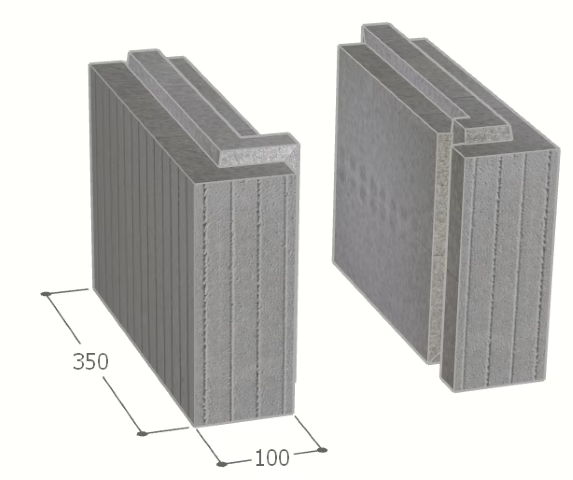

- B-HI35.AL and B-HI35.AR: 10 cm wide

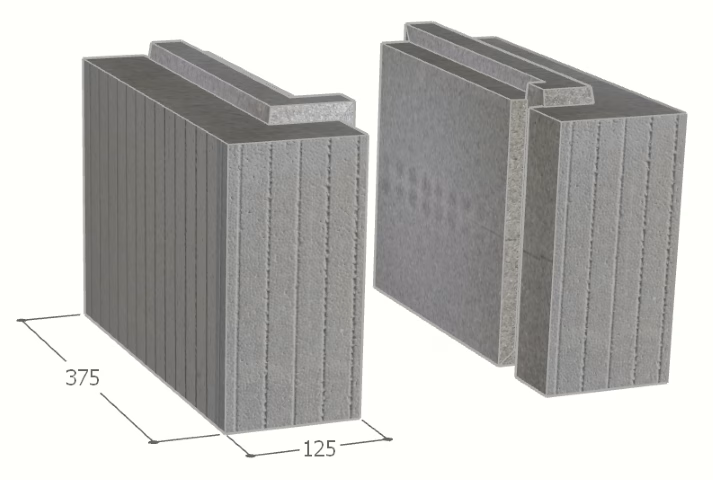

- B-HI38.AL and B-HI38.AR: 12.5 cm wide

- B-HI40.AL and B-HI40.AR: 15 cm wide

- B-HI45.AL and B-HI45.AR: 20 cm wide

- B-HI50.AL and B-HI50.AR: 25 cm wide

| Block thickness | Concrete veil 12 cm = 95 L/m². | Concrete veil 14 cm = 110 L/m². | Corner blocks Left - Right |

|---|---|---|---|

| 35 cm | B-HI35/12+19 | B-HI35/14+17 | B-HI35.AL - B-HI35.AR |

CU: 0.18 R : 5.56 |  CU: 0.19 R : 5.26 |  | |

| 37.5 cm | B-HI38/12+22 | B-HI38/14+20 | B-HI38.AL - B-HI38.AR |

CU: 0.15 R : 6.67 |  CU: 0.16 R : 6.25 |  | |

| 40 cm | B-HI40/12+24 | B-HI40/14+22 | B-HI40.AL - B-HI40.AR |

CU: 0.14 R : 7.14 |  CU: 0.15 R : 6.67 |  | |

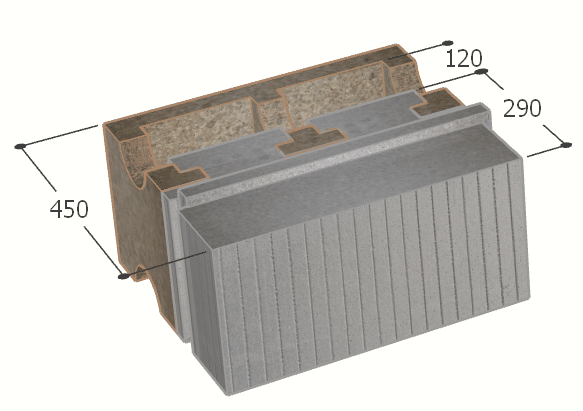

| 45 cm | B-HI45/12+29 | B-HI45/14+27 | B-HI45.AL - B-HI45.AR |

UC: 0.11 R : 9.09 |  CU: 0.12 R : 8.33 |  | |

| 50 cm | B-HI50/12+34 | B-HI50/14+32 | B-HI50.AL - B-HI50.AR |

CU: 0.09 R : 11.11 |  CU: 0.10 R : 10.00 |  |

Technical specifications

| Thermal performance | R from 5.26 to 11.11 m².K/W U from 0.19 to 0.09 W/m².K (calculation of the block without concrete and without rendering or facing) |

| Thermal insulation | Lambda wood-cement: 0.104 W/m².K Lambda graphite polystyrene: 0.031 W/m².K |

| Sound absorption | > 90 % between 100 and 5000 Hz |

| Acoustic insulation | -50 dB - 20 cm plastered wall with 12 cm concrete shell -56 dB - 25 cm plastered wall with 16 cm concrete shell |

| Flexural strength | ~ 200 DaN (wall not filled with concrete) |

| Fire resistance | > 6 hours according to ISO 834 |

| Fire classification | Non-flammable, classified M1 |

| Rot-proof | Yes |

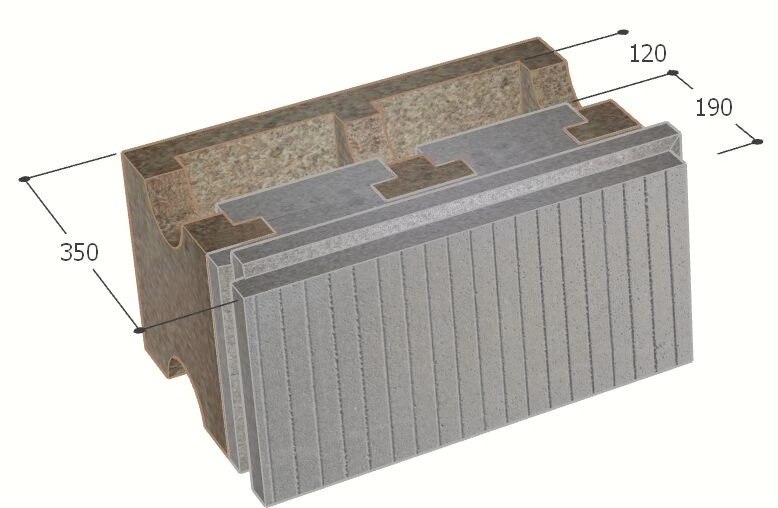

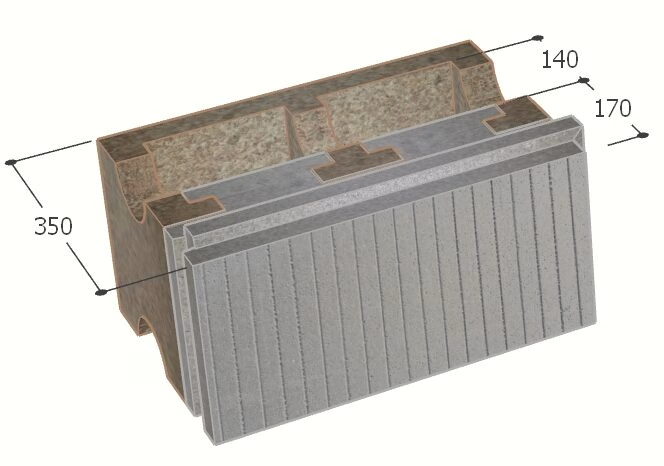

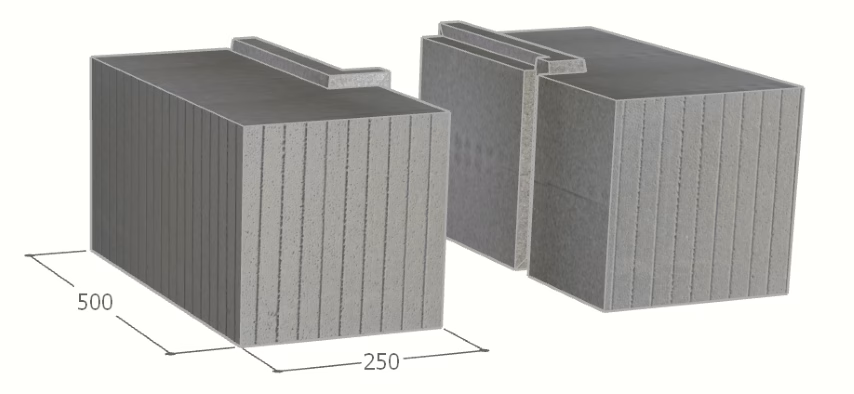

| Dimensions | |

| Width | 50 cm |

| Height | 25 cm |

| Depth | from 35 to 50 cm |

| Concrete veil | 12 or 14 cm (or more on request) |

| Polystyrene | from 17 to 34 cm |

Implementation

Cutting a block

Cut the central tenon to the required width (here 12 cm) and join the two parts together to obtain a 38 cm block. This process preserves the mortise and tenon joints for optimum hold. This cut is made on site.

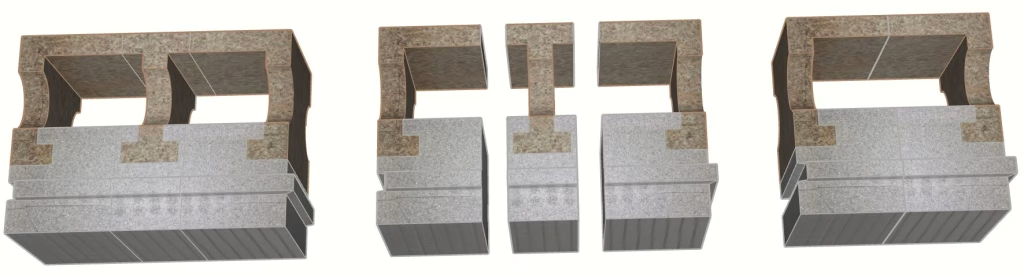

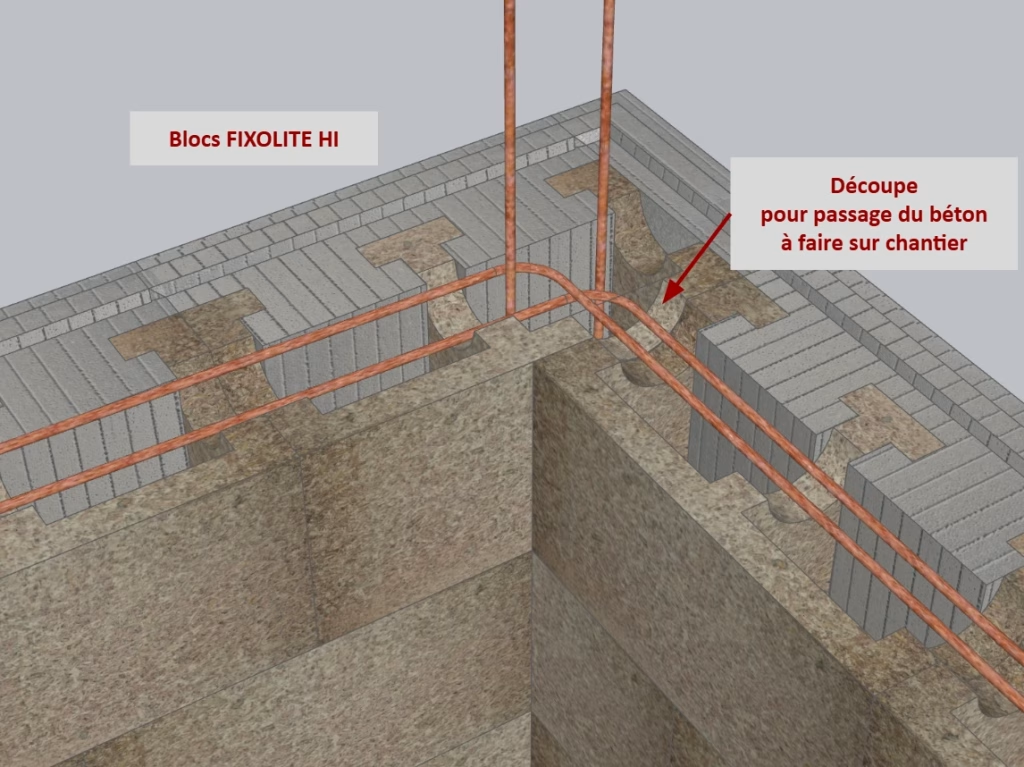

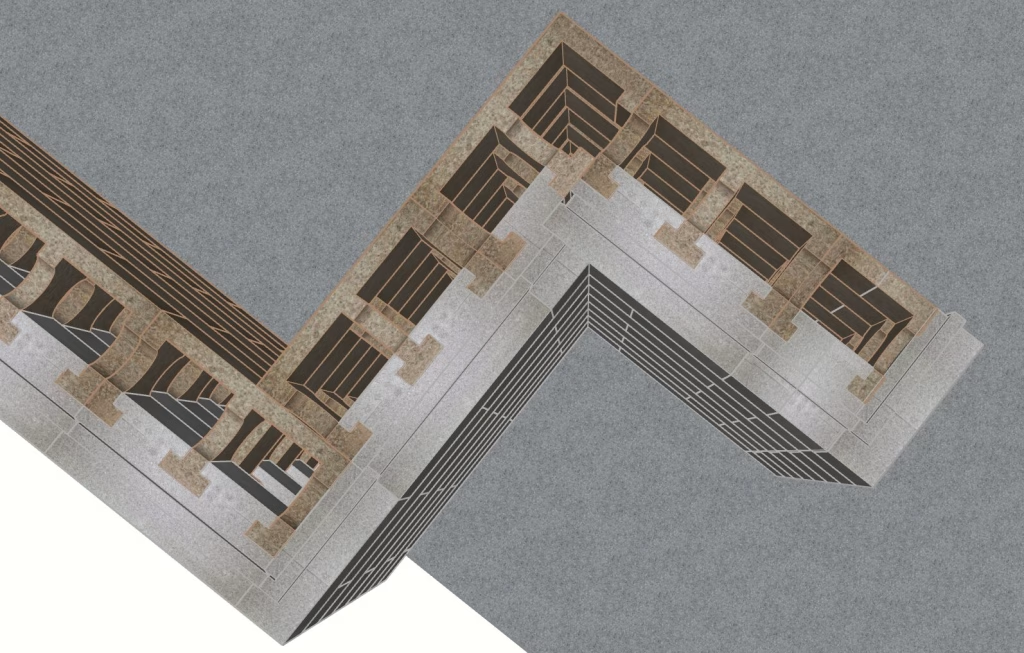

External angle

Two blocks and a corner piece (in this case the left-hand corner) form the corner.

Alternate left and right angles for cross-joint construction.

The corner block is cut to allow the ties and concrete to pass through. This is done on site.

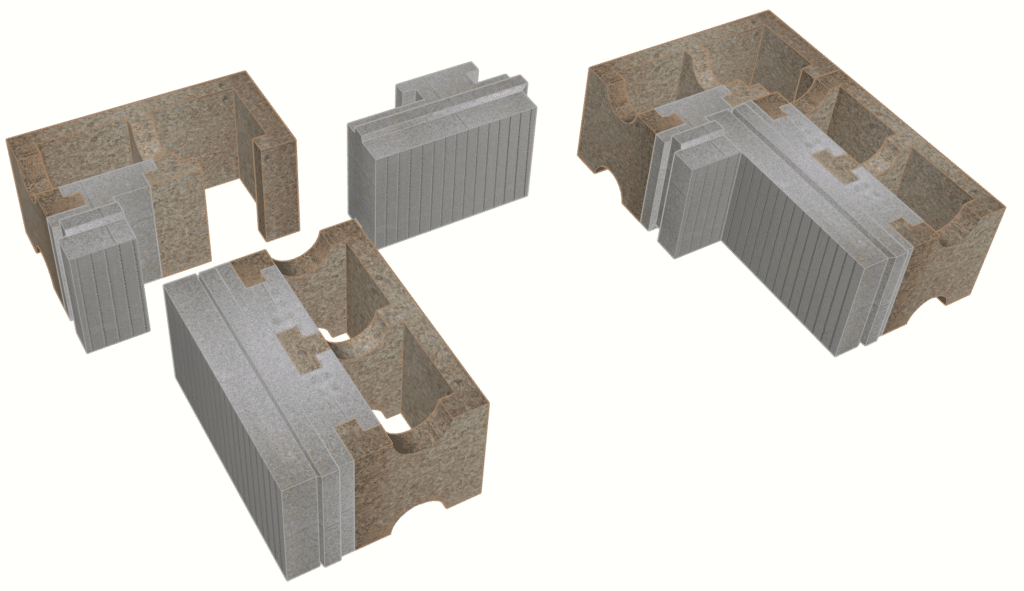

Internal angle

Two blocks form an internal angle.

The corner block (shown here in the left-hand corner) supplied by Fixolite has no opening for concrete.

The corner block needs to be cut out of the polystyrene. Here, cut 12.5 cm from the edge for the 37.5 cm block (HI 38/12+22):

50 - 37.50 = 12.50 cm.

This cutting is carried out on site.

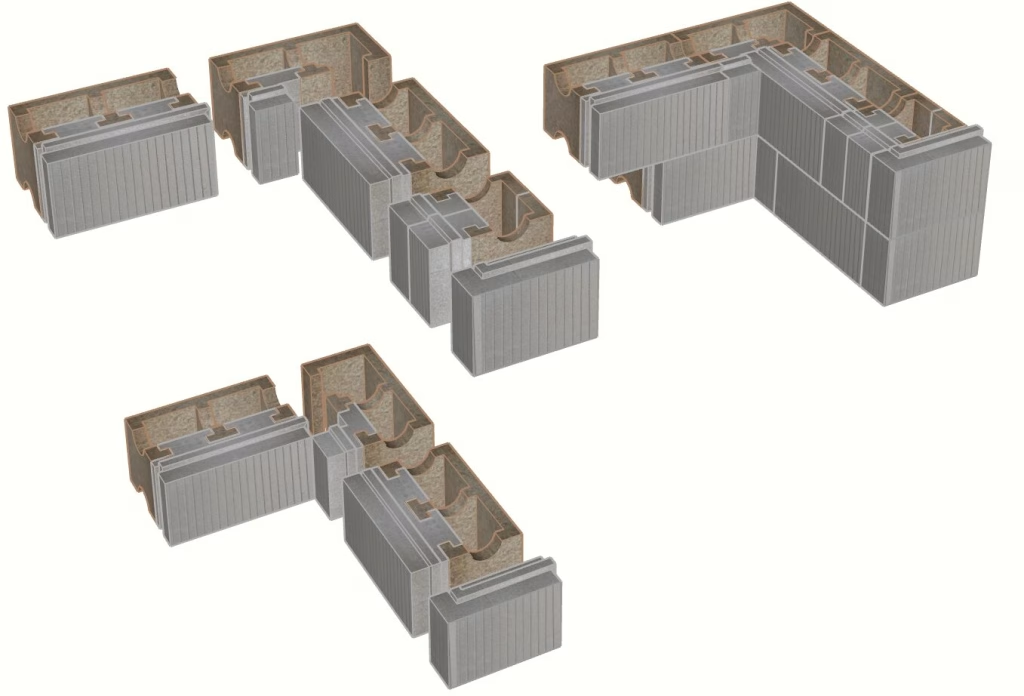

Internal angle and aperture

Create the opening using corner pieces (in this case right-angle pieces).

The left and right corner cut-outs alternate for cross-joint construction.

The diagram shows an internal corner with a finish for an opening (in this case a door).

External angle, internal angle and aperture

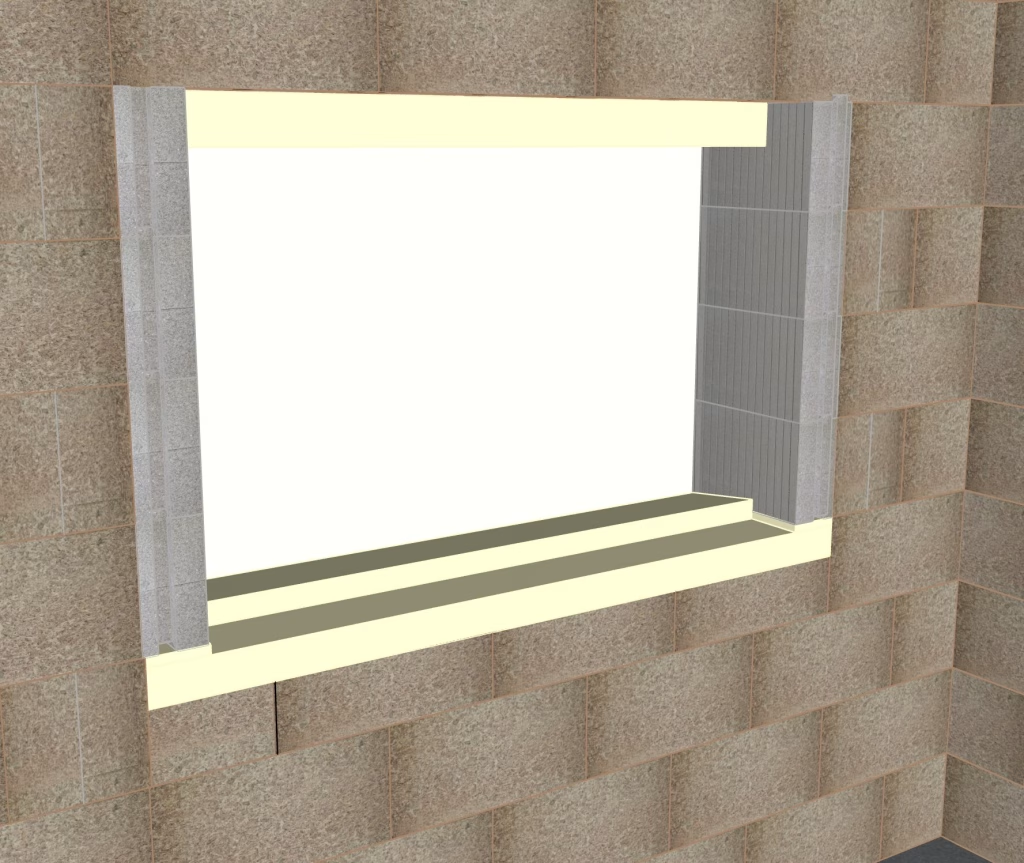

Opening with additional insulation

Adjust the height of the opening by cutting slices of block (here cut to 15 cm). Slices can be cut on site or in the factory on request.

A lintel is not necessary in all configurations. Here, there is no lintel, but in this case, a chain link must be laid between the two rows of blocks above the opening.

The sides are trimmed with corner pieces.

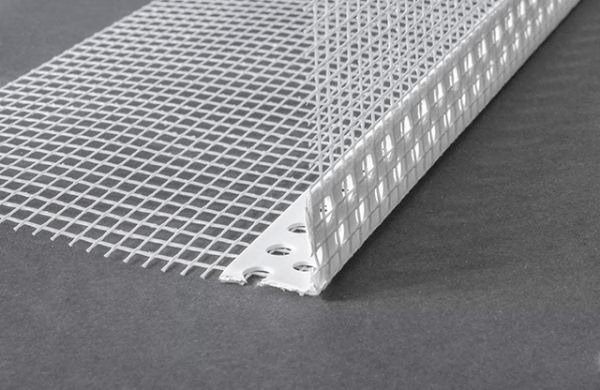

The corners and edges of the sashes are reinforced using flexible corner profiles with reinforcement:

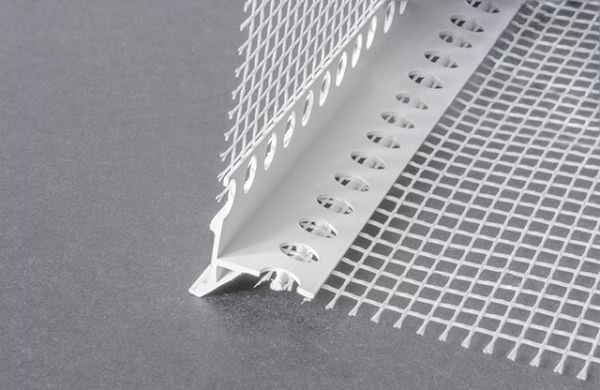

The corners above the windows or doors are reinforced with teardrop profiles:

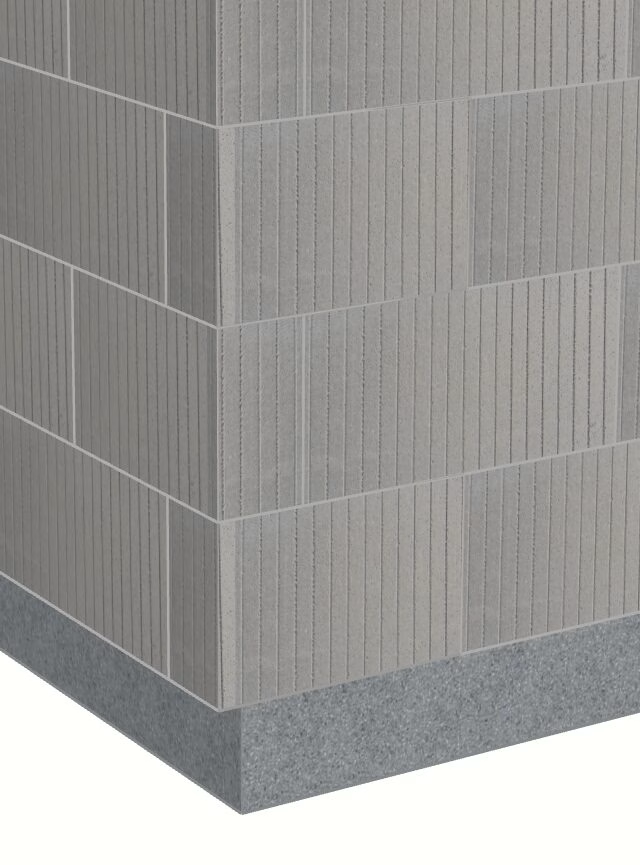

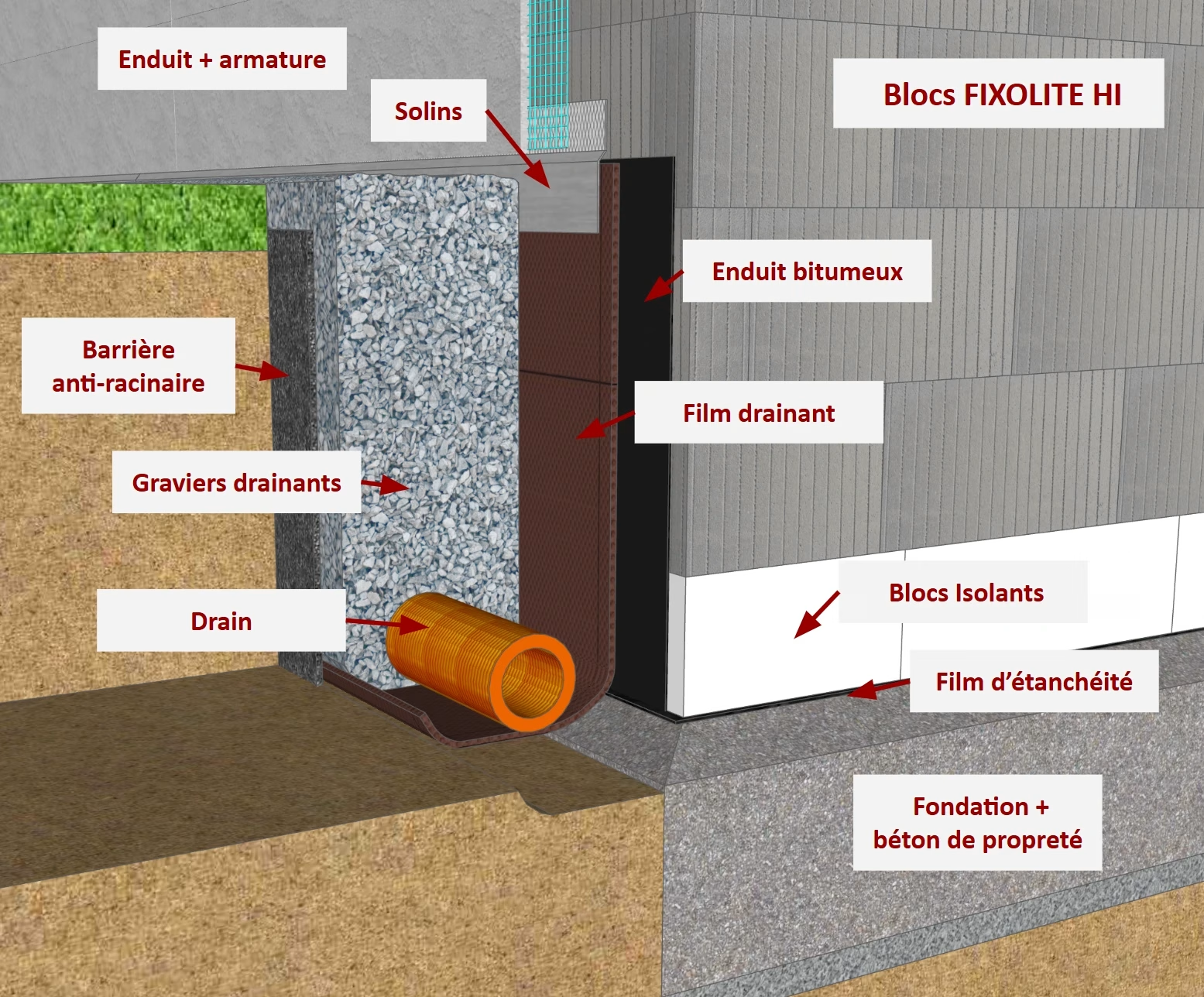

Insulation with invert

Place the blocks with the insulation protruding above the floor slab. To avoid thermal bridges, extend the Fixolite insulation at invert level with XPS panels.

Fixolite blocks can be buried in the ground. Always place a waterproofing membrane (elastomer) in front of the blocks and the XPS insulation, possibly lined with a honeycombed drainage membrane.

Foundations with crawl space

Representative diagram of the foundations with a crawl space of a recommended height of 80 cm (seen from the outside) :

| Component | Remarks |

|---|---|

| Bench blocks | This diagram also applies to blocks with internal insulation. It is advisable to embed the Fixolite block in the ground to prevent the cold from passing through. |

| Insulating blocks | A first row of insulating blocks (cellular concrete type) is recommended if the crawl space is above ground. |

| Sealing film | A waterproofing film, levelling strip or bituminous coating is applied before the first row of blocks. |

| Foundations | The reinforced concrete foundations here are of the continuous footing type. Threaded footings are used to spread the loads over a larger area so that the structure does not sink into the ground. Under the foundations, it is advisable to pour clean concrete. |

| Bituminous plaster | Between the drainage film and the Fixolite block insulation, a bituminous coating is recommended to protect the insulation from rodents and seepage. If the crawl space is above ground, the facade rendering is applied directly at this level. |

| Drainage film | The film (Delta-MS type) with a nopple structure facilitates drainage and protects the wall from impact. |

| Draining gravel | Gravel is laid over the entire height of the crawl space. They facilitate drainage and prevent the drain from becoming blocked. |

| Drain | A drain is a pipe, often made of plastic, 10 to 15 cm in diameter and perforated at the top. It is surrounded by small stones. The water in the drain must be able to drain away (well, sewer, pond, etc.). |

| Root barrier | The root barrier or geotextile keeps the drain clean and maintains its drainage properties. |

| Plaster and reinforcement | The Fixolite block is compatible with all plasters on the market. The plaster is always embedded in a fibreglass reinforcement. For external insulation with EPS, organic coatings are recommended. This coating, made from synthetic resin, is often the most economical. It produces a thin coating, sometimes in a single layer. |

| Flashings | The flashing is applied before the plaster, which partially covers it. The flashing is glued to the insulation without the use of screws, and covers the drainage film to prevent water infiltration. It also acts as a stop for facade plaster. |

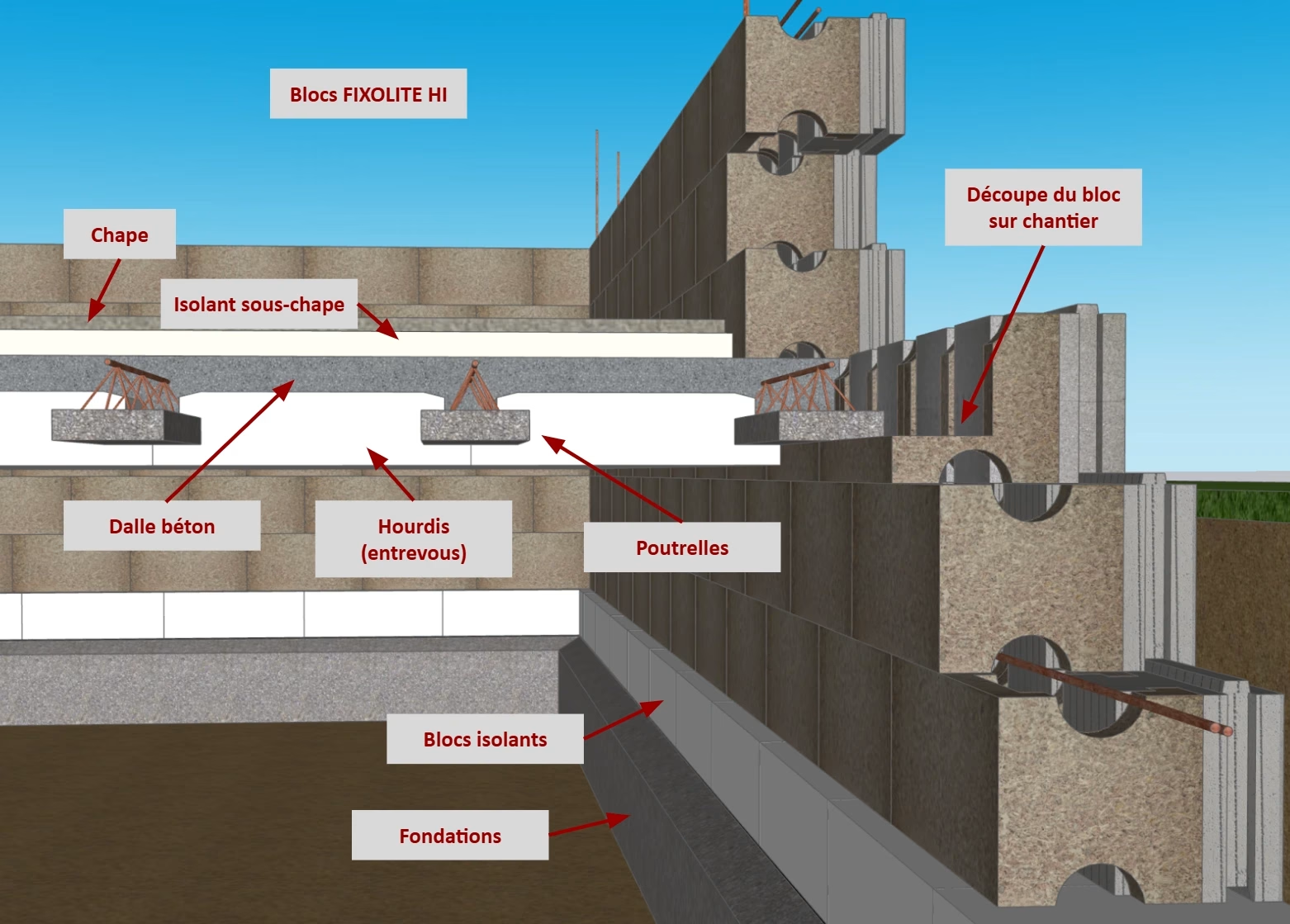

Representative diagram of the foundations with a crawl space of a recommended height of 80 cm (interior view) :

| Component | Remarks |

|---|---|

| Bench blocks | This diagram also applies to blocks with internal insulation. It is advisable to embed the Fixolite block in the ground to prevent the cold from passing through. |

| Cutting | The block is cut to the required height for laying the joists. This is usually done on site. |

| Beams | The concrete is poured up to the cut-out before the beams are laid. |

| Hourdis | The floor slabs are preferably made of polystyrene and completely enclose the joists to avoid any break in the insulation. |

| Slab | The slab is 15cm high reinforced concrete. The slab takes 3 to 4 weeks to dry. Vertical reinforcement is laid in the slab at least at each corner of the house. In earthquake zones, reinforcement is also required around each opening. |

| Underlay insulation | Insulating panels 8 to 12 cm thick. The insulation, often polystyrene in expanded (EPS) or extruded (XPS) form, is an economical solution that also has the advantage of being compatible with underfloor heating. |

| Screed | It is between 4 and 6 cm thick |