The wooden and cement formwork blocks are manufactured at Fixolite Belgium and IsoblocFixolite's Italian branch.

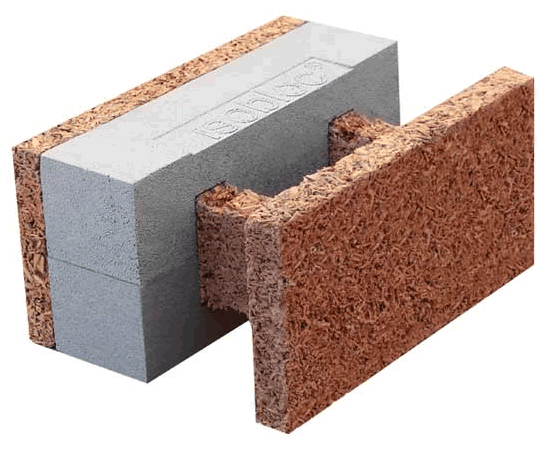

The Fixolite and Isobloc models are based on the same principle, but the designs are different.

Since the 1960s, over 600,000 homes in Europe have been built using wood-cement blocks. Fixolite and its branch Isobloc account for almost 5% of this market.

The many advantages of insulating wood cement blocks

CERTIFICATION

Fixolite and Isobloc blocks have undergone a battery of tests and have all the necessary certificates for fire resistance, thermal and acoustic insulation, mechanical resistance, environmental protection, etc.

THERMAL INSULATION

Grâce au faible poids spécifique de la fibre de bois et à l’insert en polystyrène graphite, ce bloc de coffrage présente une excellente isolation thermique, ce qui permet de réaliser d’importantes économies d’énergie.

ACOUSTIC INSULATION

Grâce à leur masse considérable, les murs en blocs de coffrage offrent une excellente isolation acoustique, ce qui en fait le matériau idéal pour la construction de bâtiments ayant des exigences élevées en matière d’isolation et de confort acoustique.

ECONOMIC

Because it's so quick to install, this 3-in-1 block is extremely economical. 3 in 1, because it simultaneously :

- supporting structure and formwork

- thermal insulation

- sound and noise insulation.

HEAT ACCUMULATION

The high specific weight of the concrete core provides advantageous energy storage times and therefore considerable thermal inertia.

Structures with thermal storage walls prevent the rapid cooling of interior rooms and avoid long heating times. This avoids thermal shocks and, consequently, over-frequent start-ups of the heating and cooling systems. The result is very high efficiency and a feeling of living comfort.

considerable.

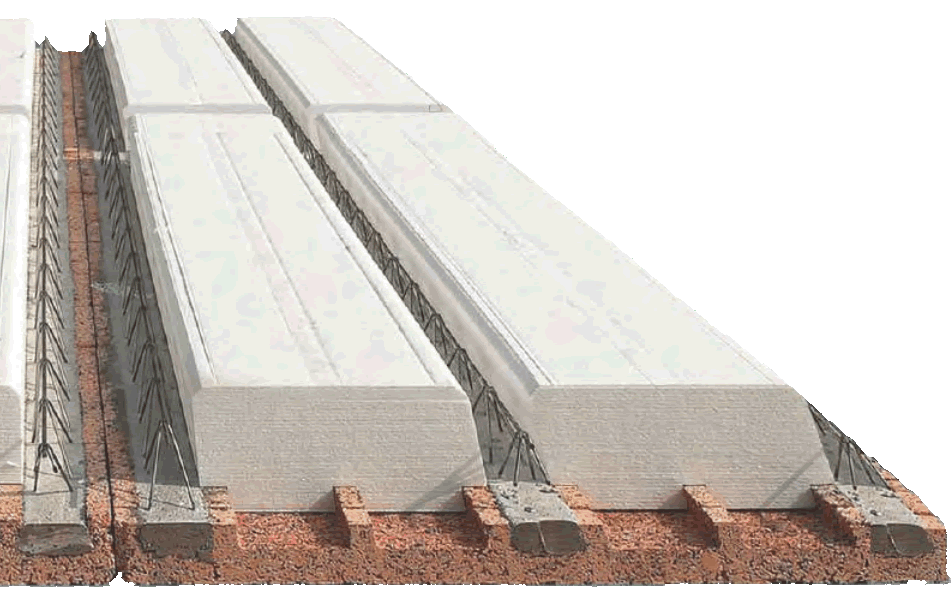

NO THERMAL BRIDGES

The dry installation of the formwork blocks (without cement mortar) and the vaults in the same material means that there are no thermal bridges at all, preventing the annoying formation of mould and condensation in the structures.

ECOLOGICAL

Isobloc blocks are made from a homogeneous mixture of mineralised spruce chips and Portland cement. The manufacturing process does not alter the insulating properties of the wood, and generates little waste because it is fully recyclable.

SELF-BUILD

The lightness, simplicity and speed of use of these blocks make them an excellent candidate for self-build. Thousands of private individuals have already built their homes using these blocks, which are proving to be an excellent plaster base.

PERMEABLE / BREATHABLE

The highly porous surface of the Isobloc formwork block allows water vapour to escape.

natural condensation to flow outwards through the transverse walls of the block, which represent around 30 % of its surface area.

FIRE RESISTANCE

The Isobloc formwork block wall is coated on both sides and has a fire resistance of 180 minutes at a temperature of 1200°C.

In terms of reaction to fire, the Isobloc formwork block is certified to fire class M1.

PARASISTIC

The Isobloc construction system is suitable for seismic zones and complies with the strict standards imposed in Italy (LLPP of July 2011).

IMPUTRESCIBLE

Le bloc bois-ciment est « minéralisé » et imputrescible : il résiste à la fois aux rongeurs et aux termites.

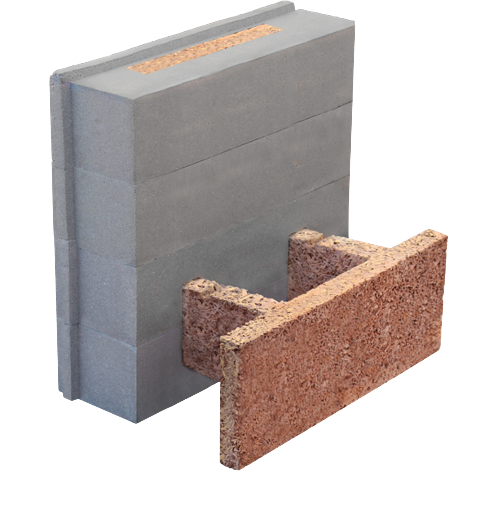

Comparison: Fixolite block vs. Isobloc block

Points in common

Composition

All the blocks are made from the same type of wood, sourced locally, and Portland cement.

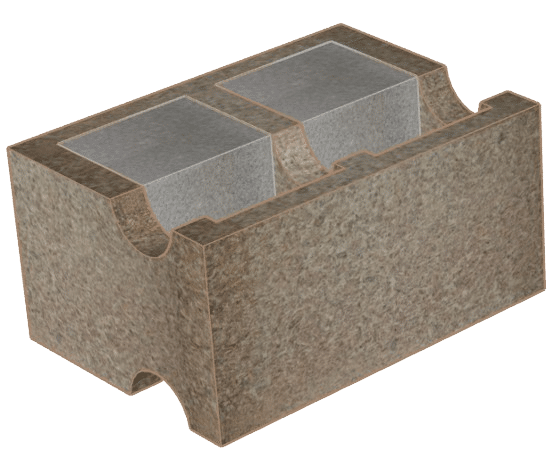

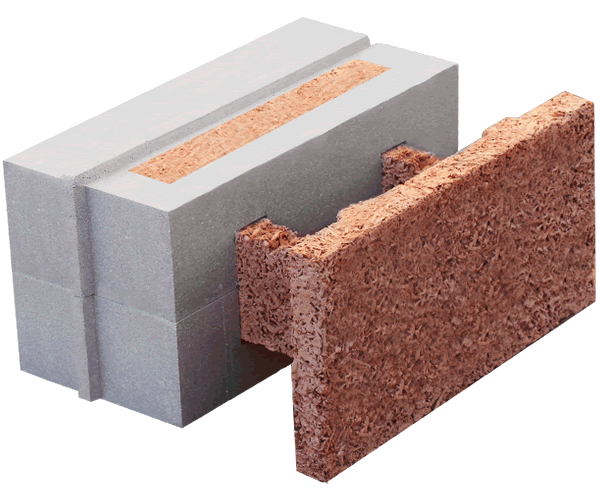

The insulation is graphite polystyrene with a lambda (λ) of 0.031 W/m²K.

Dimension

With the exception of special blocks, they are 50 cm long and 25 cm high. Thickness varies according to requirements.

You therefore need 8 blocks for 1 m² of wall.

ITE insulation

Fixolite and Isobloc are blocks offering thermal insulation from the outside.

The HI - High Insulation - range achieves an R value of 10, which is the recommended value for a passive house.

Differences

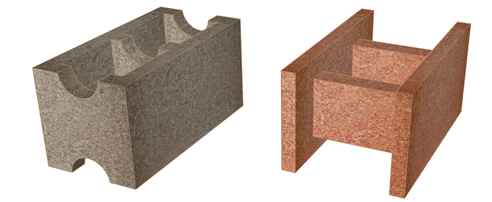

Shape

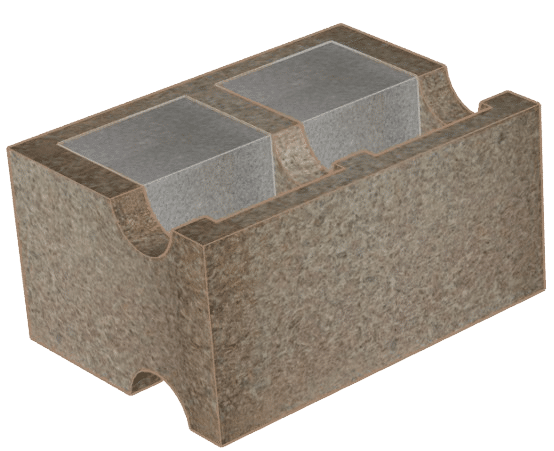

The Fixolite block has a classic shape, while the Isobloc is H-shaped.

Colour

The Isobloc block is coloured terracotta by the addition of iron oxide.

Implementation

The Fixolite block is simpler to install, as it requires fewer special blocks (angle and pass) and less cutting. On the other hand, Isobloc contains more concrete and therefore meets Italy's strict earthquake resistance requirements.

Block models

Blocks with internal insulation

This block is the most economical and offers good performance.

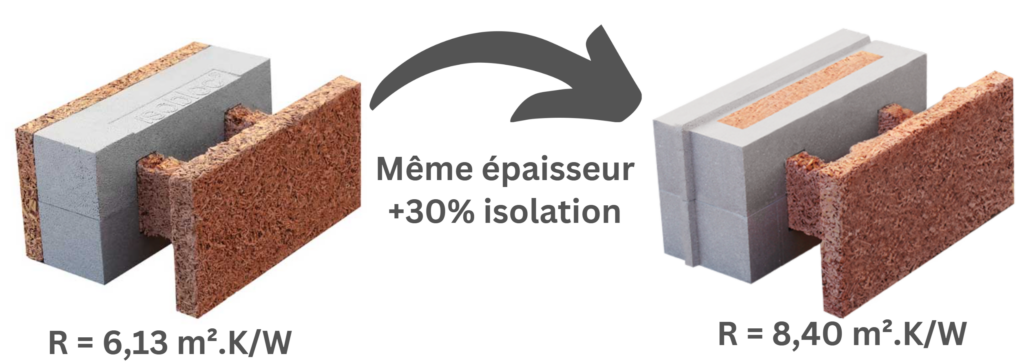

ITE blocks

This patented high-insulation block provides high-performance external thermal insulation (ETI) with a total absence of thermal bridges.

Special blocks and partition blocks

Isobloc blocks meet your most specific needs: partition blocks, pilasters, risers, edges, acoustics, etc.

Comparison: internal or external insulation

What are the advantages and disadvantages of the two principles?

→ Internal - Isobloc H block or Fixolite CL block

→ External - HI Isobloc block or HI Fixolite block

| Criteria | Internal | External | Explanation |

|---|---|---|---|

| Isobloc |  Block H |  HI block | Internal insulation (H block) vs. external insulation (HI block) |

| Fixolite |  Block CL |  HI block | Internal insulation (CL block) vs. external insulation (HI block) |

| Thermal insulation | Total absence of thermal bridges for the HI block and +30% of insulation (for the same thickness of block) | ||

| Acoustic insulation | Wood cement combined with concrete provides excellent acoustic insulation. | ||

| Fire resistance | It is the façade rendering that provides the fire resistance of the HI block. | ||

| Implementation | The H block offers better plaster adhesion without primer, and the blocks are easier to align. Always pour concrete 1/2 storey at a time using self-levelling fluid concrete. Never vibrate the concrete, as this could alter the alignment of the blocks. | ||

| Perspirant | The HI block is not breathable. A VMC is in all cases necessary or even compulsory for a class A passive house. | ||

| Acoustic comfort | The inner wall is a continuous wall of wood-cement and acts as a high-performance acoustic panel. | ||

| Cladding | The HI block is not suitable for cladding weighing more than 30kg/m² or for cladding with anchors. |

75 years of experience!

Fixolite and Isobloc have unrivalled experience in wood cement.

This longevity is testament to the expertise and quality of our products.

The manufacturing and application process has proved its worth, as shown in the promotional film below, produced over 30 years ago.